Awards / Memberships

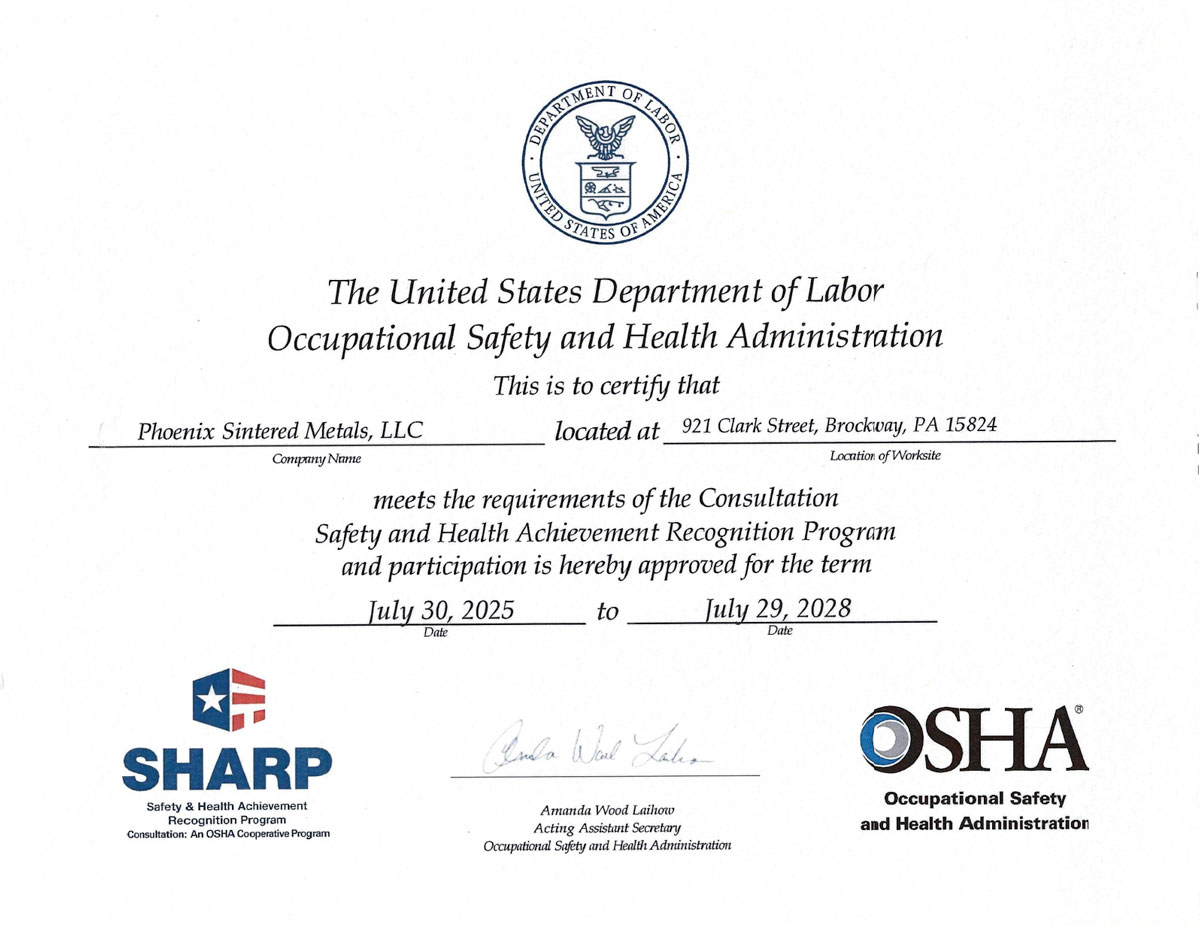

Phoenix Sintered Metals SHARP Recognized Again

Phoenix Sintered Metals SHARP Recognized Again

Phoenix Sintered Metals was re-recognized with OSHA to certify that we meet the requirements of the Consultation Safety and Health Achievement Recognition Program “SHARP” through July 2028. Phoenix has been recognized since July of 2019 and is currently 1 of only 48 facilities in the state of PA with this recognition.

Phoenix Sintered Metals Accepts Award in International Powder Metallurgy Design Competition

Blaine Stebick, Chief Technology Officer, General Manager – Galeton, and Rob Hayes, Vice President Engineering, Phoenix Sintered Metals LLC, Brockway, Pennsylvania, accepted an Award of Distinction in the Automotive Chassis Category of the 2025 Powder Metallurgy Design Excellence Awards Competition. The award was given for an anti-rotational sleeve used in electronic braking applications

They accepted the award for their company at PowderMet2025: International Conference on Powder Metallurgy & Particulate Materials in Phoenix, Arizona.

Powder metallurgy (PM) is an automated metalworking process that forms metal powders into precision components used in applications such as auto engines and transmissions, hardware, outdoor power, industrial machinery, sporting goods, defense, and firearms. More than 800 million pounds of PM parts are made annually in North America.

The competition is sponsored annually by the Metal Powder Industries Federation, an international trade association for the metal powder producing and consuming industries.

# # #

Editor's Note: For further information contact Dora Schember at

Phoenix Wins Stanley Black & Decker Best Quality Performance Award

Phoenix Wins Stanley Black & Decker Best Quality Performance Award

Best Quality Performance Award

- Continuous "A" Rating for 18+ Months for All 3 Outdoor Plants Supplied (Martin, Tupelo, Willard)

- Zero Nonconformances Experienced at Any SBD Plant for more than 2 1/2 Years

- Consistently Respond to any questions with Level of Urgency

- Early 2024 Passed Technical Audit Requirements for Power Tools Business Unit

Local Executives Accept Award in International Design Competition

Pictured Left to Right, John von Arx, Wade Farmer, DJ Sampson,

Pictured Left to Right, John von Arx, Wade Farmer, DJ Sampson,

Steve Leuschel, Blaine Stebick, and Rob HayesStephen Leuschel, Chief Operating Officer, Blaine Stebick, Chief Technology Officer and General Manger, Phoenix Sintered Metals Galeton, Galeton, Pennsylvania, Robert Hayes, Vice President of Engineering, DJ Sampson, Engineering Manager, and John von Arx, Director of Sales and Marketing, Phoenix Sintered Metals LLC, Brockway, Pennsylvania, along with Wade Farmer, Global Supply Chain Manager, Muncie Power Products, Inc., accepted an Award of Distinction in the Industrial Motors, Controls & Hydraulics category of the 2024 Powder Metallurgy Design Excellence Awards Competition. The award was given for a piston brake spring-return assembly, made for Muncie Power Products, Inc.

They accepted the award for their companies at PowderMet2024: International Conference on Powder Metallurgy & Particulate Materials in Pittsburgh, Pennsylvania.

Powder metallurgy (PM) is an automated metalworking process that forms metal powders into precision components used in applications such as auto engines and transmissions, hardware, outdoor power, industrial machinery, sporting goods, defense, and firearms. More than 800 million pounds of PM parts are made annually in North America.

The competition is sponsored annually by the Metal Powder Industries Federation, an international trade association for the metal powder producing and consuming industries.

# # #

Editor's Note: For further information contact Dora Schember at

Powder Metallurgy Design Excellence Award (2021)

Powder Metallurgy Design Excellence Award (2021)

Rob Hayes, VP of Engineering, John von Arx, Director, Sales & Marketing, and Blaine Stebick, VP of Technology and Business Development, Phoenix Sintered Metals LLC, Brockway, Pennsylvania, along with Andy Shupe, Director of Gear Engineering and Brian Thisse, Director of LV Application Engineering, Dana Corporation, and Mark Ruddy, Apex Sales, accepted a Grand Prize Award in the Automotive Chassis Category of the 2021 Powder Metallurgy Design Excellence Awards Competition. The award was given for a stepped planetary gear used in a ridged rear axle gear box for battery electric light commercial vehicles.

BROCKWAY PLANT

921 Clark Street

Brockway, PA 15824

Tel: 814.268.3455

GALETON PLANT

1251 Rte. 6 W

Galeton, PA 16922

Tel: 814.435.6541

Operational Excellence is more than just an activity, it is the way we do business.

Follow Us: