Powder Metal Parts for Sporting Arms

Phoenix Sintered Metals, a U.S.-based manufacturer specializing in precision-engineered conventional powder metal components. Serving multiple markets, they have over 20 years’ experience of serial production for major Firearm OEMs. They have provided several Firearm components with a better cost solution and more consistent dimensional process verses traditional MIM technology.

Their vertically integrated facility in Pennsylvania handles everything from design and prototyping to full automated production and secondary operations, ensuring full control over quality, timing, and cost. With Dual capabilities at 2 mfg. locations and installed capacity to address any risk mitigation concerns.

The Phoenix Sintered PM/Powder Metal process provides Lower cost material with far fewer steps in the manufacturing process. PM process has 3 basic steps, Powder / Compaction / Sintering. Similar to MIM any additional processing, i.e., Heat treat, machining, plating/coating is possible. For parts produced in PM, the process yields a tighter tolerance and part to part consistency verses MIM. Contact us and we can Collaborate with your engineering group to assess components in which PM would be a solution to improve performance, reduce cost, or streamline your production processes .

Phoenix would supply a value solution for the listed components below.

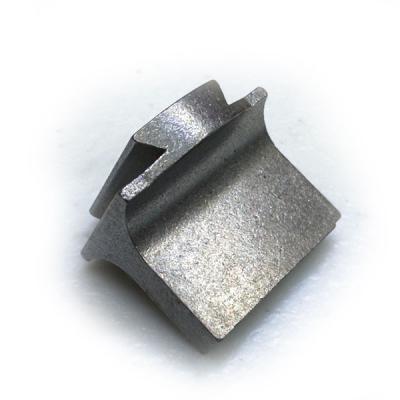

Hammers (Iron and Stainless)

Triggers (Iron and Stainless)

Sears

Pendulum Weights

Recoil Lugs

Release Levers

Ejector Blanks

Barrel Catch Blanks

Selectors

Bolt Baffles

Camlocks

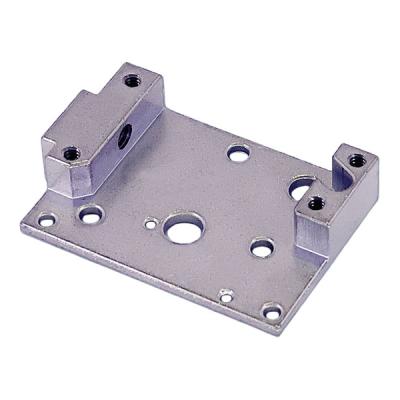

Trigger Brackets

Safety Bars

Yokes

Multiple Model Front Sights

Multiple Model Rear Sights

Sight Elevators

Rear Folding Leaf Sights

Multiple Model Scope Mounts (Iron and Stainless)

Powder Metal Parts for Sporting Arms Applications

BROCKWAY PLANT

921 Clark Street

Brockway, PA 15824

Tel: 814.268.3455

GALETON PLANT

1251 Rte. 6 W

Galeton, PA 16922

Tel: 814.435.6541

Operational Excellence is more than just an activity, it is the way we do business.

Follow Us: